2025 will be the first year of MicroLED mass production: the most perfect display

Recently, several leading panel manufacturers such as Shenzhen Tianma A, BOE A, and AUO will start mass production of MicroLED-related production lines in 2025, and the large-scale commercialization of MicroLED technology may not be far away. “We believe that after the commercialization of large-screen glass-based MicroLED, the next application should focus on automotive displays,” said Qiu Yubin, senior research vice president of TrendForce, to reporters.

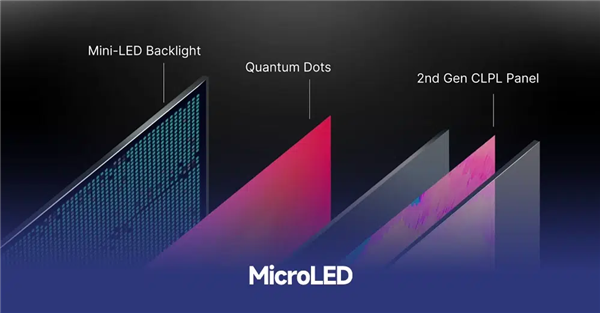

MicroLED technology, which has high brightness, wide color gamut and high reliability, has been regarded as the “next generation display technology”, but due to the suspension of MicroLED technology research and development for Apple Watch, some people are confused about the future of MicroLED technology. Analysts believe that due to its superior performance, MicroLED is irreplaceable in many fields.

The first is the automotive field. “The application of MicroLED will most likely be locked in automotive use, largely due to the high brightness of MicroLED and the very low pixel fill rate. High brightness can be used in central control and instrumentation. Even the AR HUD that will be equipped in many high-end cars is a potential direction for MicroLED applications.

As for the low pixel fill rate, it means that Micro LED display technology can achieve high brightness and provide very good transparency (up to 70%) at the same time, which is not comparable to large displays such as OLED. “Qiu Yubin said, “Because the price difference between high-end and low-end cars is very large, as long as car manufacturers are willing to introduce it, even if the initial cost of Micro LED transparent displays remains high, car manufacturers are still able to use the premium of high-priced cars to make up for the high cost.”

In addition, Qiu Yubin believes that silicon-based MicroLED also has development opportunities in the AR field, mainly because AR glasses have extremely high requirements for the size and brightness of the optical machine.

Under this circumstance, TrendForce predicts that the output value of MicroLED chips will reach US$5.8 billion by 2028, with a compound annual growth rate (CAGR) of 84% from 2023 to 2028.

At present, there are more and more news about the mass production of MicroLED.

“Tianma MicroLED production line plans to lock in all processes by the end of this year and achieve full process connection. Next year, we will achieve yield and efficiency improvements based on the production line products, with the goal of achieving small-batch delivery by the end of 2025. ” Xi Kerui, deputy director of Tianma Microelectronics MicroLED Research Institute, said in an interview with a Cailian reporter at the 2024 Tianma Microelectronics Global Innovation Conference held recently.

It is worth mentioning that in addition to the MicroLED production line news, Shenzhen Tianma A, Hisense Visual, and Qianzhao Optoelectronics also jointly released the boundless crystal link MicroLED display technology product at the 2024 Tianma Microelectronics Global Innovation Conference. Relevant parties introduced on the spot that this technology is currently the world’s highest PPI MicroLED display technology.

“The products on site are samples in our development stage. We have completed product development based on these samples. We will continue to iterate in the future and expect to release more amazing seamless splicing products with our partners next year.” Xik Rui revealed to a Cailian reporter.

In addition, according to the official microblog of Zhuhai State-owned Assets Supervision and Administration Commission, BOE Zhuhai MLED project was officially launched in September this year. The project was jointly established by BOE’s Crystal Core Technology and Huacan Optoelectronics (300323.SZ), with a total investment of about 1 billion yuan. It is expected to realize the lighting and full mass production of MLED direct display products in the first quarter of 2025; according to OLEDindustry, AUO’s 4.5-generation MicroLED production line was completed in October this year and is expected to enter the mass production stage in 2025.

However, despite the encouraging progress made by many manufacturers, the entire industry still has difficulties to overcome in its development.

Geng Yi, executive vice secretary-general of the China OLED Industry Alliance, admitted at the Tianma MicroLED Display Technology Forum that there are still four major difficulties in the industry. They are: mass production technology is still difficult, and many technical bottlenecks have hindered its mass production process; production costs remain high, and production equipment requires high-precision and high-speed performance, and early research and development and manufacturing costs are high; industrial links are relatively scattered, the industrial chain is longer, the industrial system is more complex, and companies are more competitive in the supply chain; the lack of unified standards and specifications has led to differences in the definition, specifications, and interfaces of MicroLED products.

Kazam is Focused on creating and reporting timely content in technology with a special focus on mobile phone technology. Kazam reports, analyzes, and reviews recent trends, news and rumors in mobile phone technology and provides the best possible insights to enhance your experience and knowledge.