Apple achieves another breakthrough: iPhone Air’s USB-C port uses 3D printing technology.

Apple’s iPhone Air USB-C port uses 3D printing technology.

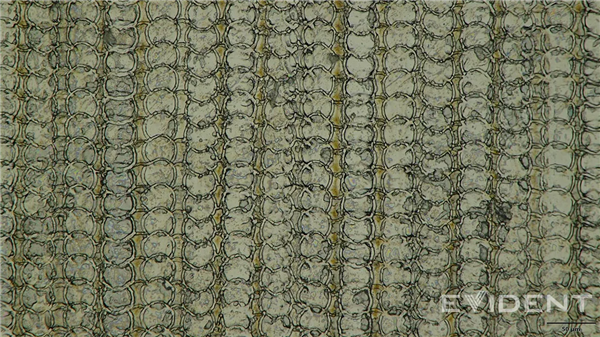

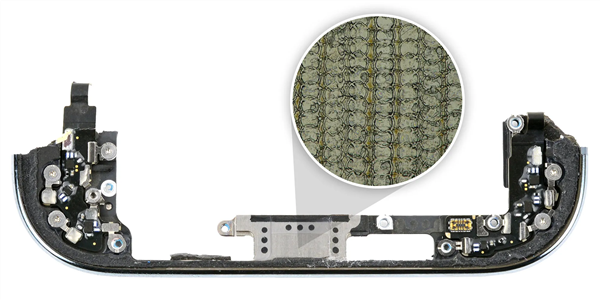

Researchers examined the iPhone Air’s USB-C port under a DSX2000 microscope and discovered a detail: the surface of the USB-C port has a circular texture resembling chain links, which is quite unique.

Early reports speculated that Apple might have used binder jetting, a 3D printing process that uses a binder to bond powder materials together. However, under a microscope, the texture created by binder jetting does not follow the same pattern as that seen on the USB-C interface, leading researchers to conclude that Apple did not use binder jetting.

According to iFixit, Apple likely used pulsed laser ablation technology, which uses high-intensity, short-pulse lasers to vaporize solid targets, ejecting atoms or clusters of atoms, which are then redeposited to form thin films or coatings.

Apple has previously emphasized the environmental advantages of 3D-printed titanium and linked this choice to Apple’s 2030 carbon neutrality goal. By replacing stamping with 3D printing, Apple will save more than 400 metric tons of virgin titanium this year. The environmental benefits of reducing metal mining are obvious, and the economic benefits are self-evident.

It’s worth noting that this year, all Apple Watch Ultra 3 and the titanium Apple Watch Series 11 cases are made using 3D printing technology, using 100% aerospace-grade recycled titanium powder.

Using 3D printing, an additive manufacturing process, material is printed layer by layer, making the product as close as possible to the desired final shape. Machining forgings has traditionally employed a subtractive process, which removes excess material from the raw material to form the desired product. This shift allows the titanium cases of the Ultra 3 and Series 11 to use half the raw material of their predecessors.

Apple says it aims to make its carbon footprint completely carbon neutral by the end of 2030, including its production supply chain and the entire lifecycle of all its products. This is Apple’s ambitious goal, and all the electricity used to produce the Apple Watch now comes entirely from renewable energy sources such as wind and solar power.

Kazam is Focused on creating and reporting timely content in technology with a special focus on mobile phone technology. Kazam reports, analyzes, and reviews recent trends, news and rumors in mobile phone technology and provides the best possible insights to enhance your experience and knowledge.