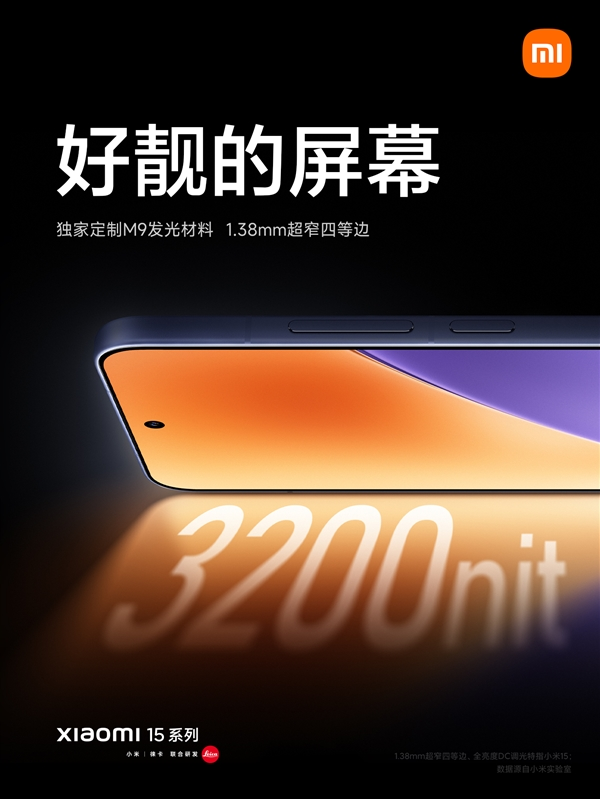

Xiaomi Mi 15 screen parameters released: first 1.38mm ultra-narrow four-sided straight screen

Xiaomi 15 is equipped with a super sunlight screen with an amazing 1.38mm ultra-narrow four-sided surface. It also has an exclusive customized M9 luminous material and a dual micro-cavity screen structure. The luminous efficiency is unrivaled, the screen power consumption is reduced by 10%, and it supports full-brightness DC dimming and full-screen AOD lock screen.

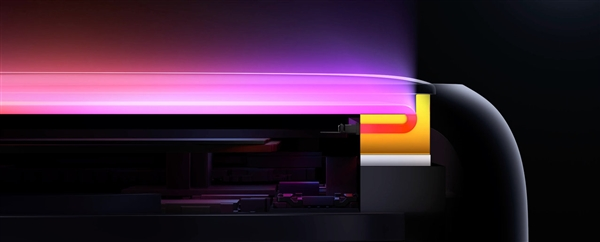

It is reported that Xiaomi 15 uses LIPO packaging, which is essentially using photosensitive resin to protect the COP cables. Just like amber can perfectly protect the insects inside after solidification, liquid photosensitive resin will also solidify into a solid after being irradiated with blue light, protecting the internal COP cables.

It not only allows the screen glass to shrink inward and reduce the bottom border, but also allows the light-emitting panel itself to be better protected, improving the reliability of the screen.

In the end, Xiaomi 15 achieved an ultra-narrow 1.38mm four-sided surface. The official mentioned that before curing, the photosensitive resin was sealed in the mold together with the screen; the wavelength used for light curing must penetrate the mold with poor light transmittance.

After many verifications and adjustments, Xiaomi LIPO finally chose 480nm blue light for photocuring to shorten the time required for photocuring.

When separating from the mold, it is crucial to ensure the yield during demolding. Therefore, the light curing of the mold is another complete set of self-developed light curing production line. This set of molds needs to be redone after being used about 10 times to ensure the stability of the shape.

Kazam is Focused on creating and reporting timely content in technology with a special focus on mobile phone technology. Kazam reports, analyzes, and reviews recent trends, news and rumors in mobile phone technology and provides the best possible insights to enhance your experience and knowledge.